Screen Printing

[wpcol_3fifth id=”” class=”” style=””]

Screen Printing, also know as silk screening, is a technique used to print customized artwork, text, and logos on shirts, hoodies, bags, or any other type of clothing. A screen is burned with your design and placed over the item being printed on. Then the ink is forced through the screen with a squeegee onto the item, which leaves the design on the item. After this, the item is cured by passing through a heat dryer.

Artwork:

The first step in screen printing is coming up with a design. We have an experienced graphic artist who will help you to get your ideas into an image, and prepare it for screen printing. It is preferred to use vectorized images (.ai, .eps) for screen printing because they can be resized however big or small you want without any loss of image quality. After your art is ready, the artist will separate it into each of it’s component colors, as each color will require a different screen.

Screen Preparation and Exposure:

A Screen for printing consists of a wooden rectangular mount with a mesh screen stretched over it. The screens are coated with emultion, which will block the ink from passing through once it is dried. Your design is placed on a UV light box with the screen over top of it and allowed to “burn” into it. The UV light reacts with the emultion and cures it, causing it to become hard. Anywhere the design is against the screen will not be cured by the light, and is easily washed out with water. The area where the design is will allow ink to pass through it, while the rest of the screen will not. The screen is now ready to be used for printing.

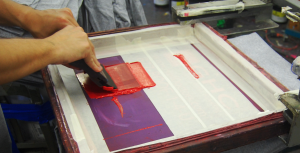

Printing:

The screen is then attached to a screen printing press, which consists of a series of screen clamps and t-shirt palettes. Every color screen for the design being printed must be attached and lined up with each other to print correctly. In our shop, we have 5 multicolor manual presses, as well as a 10 color automatic press. When the screens have been aligned properly, our printers will put a t-shirt or other garment on each palette. Each screen meets the t-shirt and the printer will use a squeegee to push the selected color ink through the screen into the shirt, leaving the design printed there. This is repeated for every color in the design. Some colors require being printed twice, such as light colors on dark colored shirts. Once all colors have been applied, the t-shirt is removed and run through a heat dryer where the ink will cure, making it permanent on the shirt and washable without removing the ink. At this point, the printing process might be repeated in the case of a shirt with a front and a back print.

[/wpcol_3fifth] [wpcol_2fifth_end id=”” class=”” style=””]